1. The chassis of this model is designed and manufactured according to OK-class standards, using 30 mm chrome-molybdenum steel tubes, offering high strength and resistance to deformation.

2. Utilizes automated TIG welding technology to minimize manual errors, enhancing welding precision and quality.

3. The frame undergoes primary heat treatment, significantly reducing material stress and preventing chassis deformation.

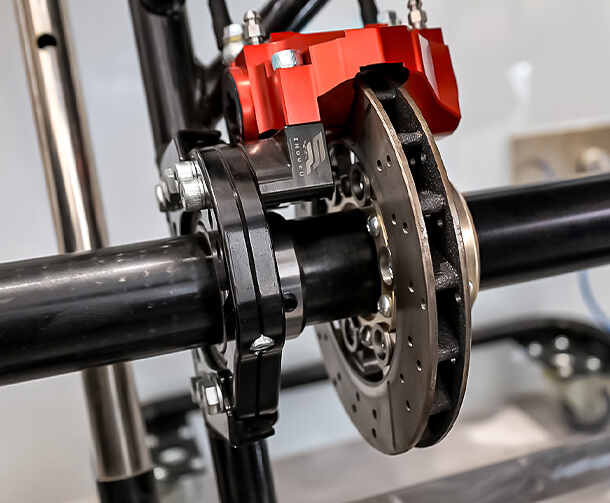

4. Equipped with the Ibox 9 braking system, an upgraded version of the Ibox 8. New solutions adopted give unique heat dissipation effects concerning pump and calipers, resulting in reduced brake oil temperatures. The rear brake caliper is forged in a single piece: inside there are two pistons with stroke recovery. It features a 180*17 mm hydraulic floating brake disc, providing sensitive braking effects, fast response, and effectively shortening braking distance (carbon ceramic brake discs are optional).

5. 50*2*1020 mm rear axle, paired with CNC-machined magnesium axle hubs.

6. Lightweight design: The chassis extensively uses magnesium alloy and aluminum alloy components, including pedals, axle hubs, wheel rims, steering wheel and sprocket carriers.

7. Front torsion bar allows drivers to adjust chassis stiffness according to track conditions.

30 mm chrome-molybdenum steel tubes utilize automated TIG welding technology.

Equipped with the Ibox 9 braking system, an upgraded version of the Ibox 8. New solutions adopted give unique heat dissipation effects concerning pump and calipers, resulting in reduced brake oil temperatures. The rear brake caliper is forged in a single piece: inside there are two pistons with stroke recovery. It features a 180*17 mm hydraulic floating brake disc, providing sensitive braking effects, fast response, and effectively shortening braking distance (carbon ceramic brake discs are optional).

CNC-machined aluminum pedals

Adjustable footrest allow drivers to customize its position according to their driving habits.

CNC-machined magnesium axle hubs improve performence and reduce weight.

Spindles with cast stainless steel body, with pressed lever and removable wheel axle by means of a fixing bolt. Steering tie rods made from aluminium material with aluminium bushes to fix uniball. eccentric adjuster allow driver to choose the most suitable setup, according to use (indoor track, outdoor track, short, quick, mixed...). Each front wheel is mounted on four bearings to reduce axle loads as much as possible.

Equiped with 130/212 mm magnesium wheel rims

Front torsion bar allows drivers to adjust chassis stiffness according to track conditions.

To achieve a lightweight design, the steering wheel is constructed from magnesium material, wrapped in PU leather. Adjustable steering base allowing drivers to customize its position according to their driving habits.

| Product Name | OK Kart Chassis |

| Suitable Engine | IAME X30, ROK, ROTAX |

| Frame Material | 30crmo Chrome-molybdenum Steel |

| Tubular Frame | Ø30-32×2 mm |

| Frame Tech | TIG+Laser Welding |

| Wheelbase | 1040 mm |

| Axle | Ø50x1020 mm |

| Brake | iBox Hydraulic Ventilated Brake System |

| Wheel Rim | Magnesium |

| Tank | 6.5 Litre |

| Seat | Fiberglass Seat with Leg Support |

| Steering Wheel | Magnesium 4-spoke Wheel |

| Safety | Protective Bracket, Integral Chain Cover, PE Bodywork |